What is WMS?

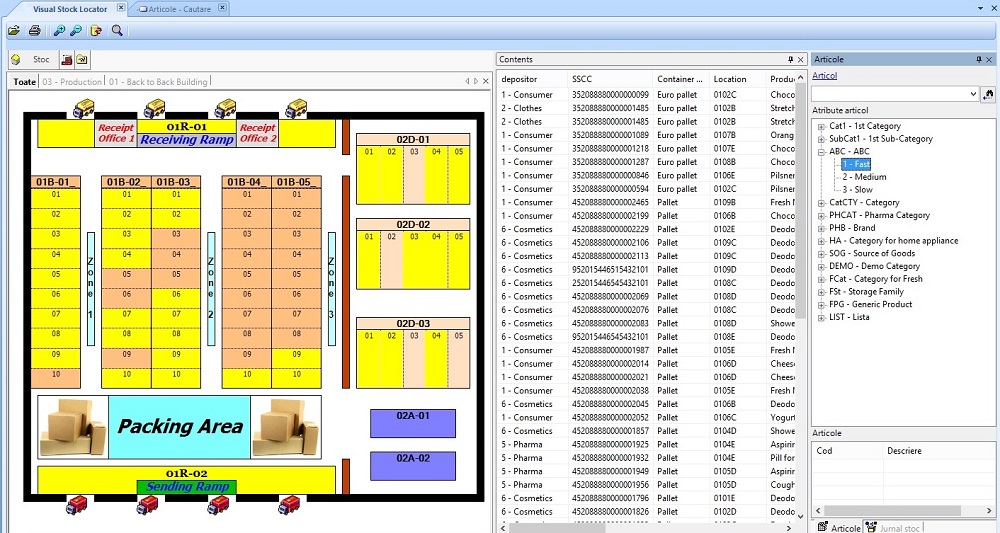

WMS (Warehouse Management System) is a component of the supply chain, whose role is to control the movement of goods within warehouses. WMS solutions automate and optimize the activities of receiving, storing, collecting and shipping of goods, constantly providing real-time information on inventory status and storage space. In addition to this, modern WMS systems can also cover packing, inventory or replenishment activities.

A WMS solution is made up of both the software component – the actual application – as well as the hardware: servers, mobile scanning devices and bar code printers. It can be standalone or it can be integrated with the ERP system, in this case representing a complete solution that covers all the activities, from taking orders from customers and issuing invoices to loading products for delivery.

What are the benefits?

- Helps optimize stocks

- Increases the accuracy of the picking process

- Facilitates inventory processes

- Allows traceability of lots

- Significantly reduces the time spent handling goods

- Provides real-time inventory information

- Contributes to the increase of productivity of the warehouse employees

- New employees integrate in a much shorter time

- The risk involved in personnel rotation is eliminated

- It offers increased visibility on all the activities carried out in the warehouse

What activities does a WMS system cover?

- Reception of goods – Accomplished with mobile barcode readers, by means of which merchandise is scanned when it arrives at the warehouse. Supply orders are created in the ERP system, and then exported to WMS. At the time of receipt, the differences between them and the results of the scanning of the goods are recorded and sent back to the ERP for order updates.

- Warehouse placement – Due to WMS, warehouse employees have a clear picture of the space available for storage. The merchandise can be placed on the basis of the suggestions offered by WMS, so that access to it can be done as quickly as possible.

- Picking – It represents the activity of collecting goods from the warehouse and is done on the basis of the customer orders registered in the ERP system. Employees view the orders directly on their mobile device and perform the picking according to the optimal route suggested by WMS. The modern technologies of the WMS system field allow picking activity via different methods, such as: pick-by-light or pick-by-voice.

- Packaging and Labeling – After picking, the customer orders are packaged in order to be delivered to their destination based on the delivery lists generated by WMS. With a thermal printer, each barcode can be attached to each order so that their identification can be done faster.

- Delivery – Orders are loaded in cars according to predetermined rules, depending on the location of where they are to be delivered.

- Inventory – The entire process is done using WMS, based on the inventory lists generated. The use of barcode scanners contributes to an increase in accuracy and the completion of inventory processes in a much shorter time.